Key Takeaways:

-

Vodaland’s wastewater management systems, including oil/water separators, grease traps, and solid waste interceptors, help businesses stay compliant and protect the environment.

-

Their fiberglass oil/water separators use gravity and coalescing filters for efficient pollutant removal and offer durability, corrosion resistance, and easy installation.

-

Industry-specific solutions serve a wide range of businesses—from auto shops to breweries—ensuring smooth operations and regulatory compliance.

-

Investing in high-quality separation systems not only prevents costly fines and damage, but also supports sustainable, clean business practices.

Behind every clean and compliant business operation is a system working hard beneath the surface—often literally. Whether you’re running an auto shop, designing a brewery, or overseeing a large-scale infrastructure project, managing what goes down the drain is just as critical as what goes out the door. That’s where oil/water separators, grease traps, and solid waste interceptors come into play.

These systems serve as a frontline defense against environmental violations, fines, and equipment damage. And for businesses aiming to hit their wastewater regulations marks without breaking stride, Vodaland offers a range of smart, durable solutions designed to meet real-world demands.

Who Needs Oil/Water Separation?

From fast-paced car washes to industrial manufacturing plants, the industries that benefit from Vodaland’s separation systems are as varied as the waste they produce. Auto shops, service stations, and equipment yards often contend with oily runoff. Food service businesses face fats and grease, while wineries and breweries must manage heavy solid waste.

In each case, the right separation system ensures smoother operations while keeping facilities compliant with EPA guidelines and municipal codes. Oil and grease discharged into storm drains or sewer systems can result in significant penalties—and more importantly, they contribute to long-term environmental harm. Choosing the right separator is more than a regulatory checkbox; it’s a commitment to cleaner practices and sustainable operations.

So, How Does an Oil Water Separator Work?

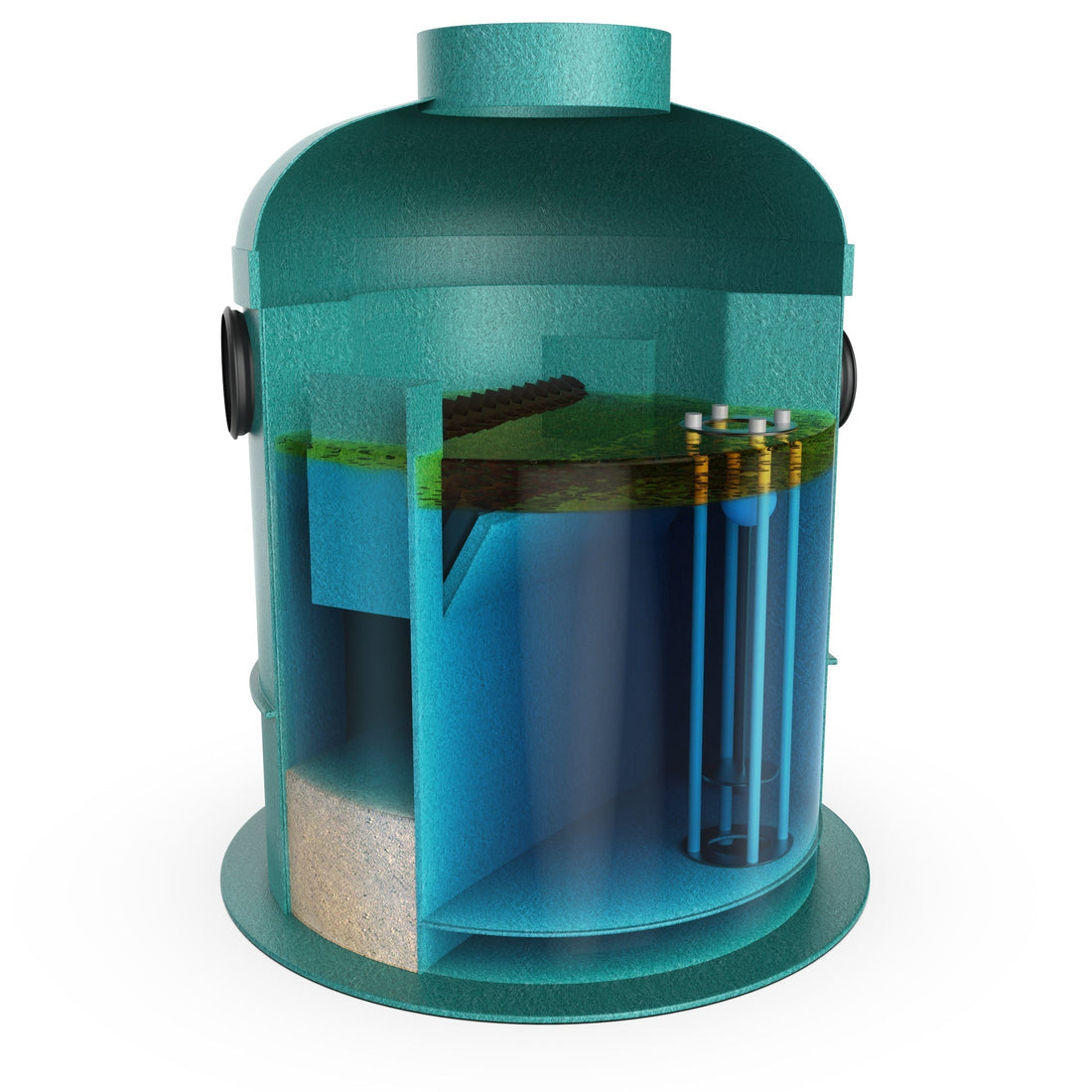

Vodaland’s systems use gravity and smart filtration to separate oil from water before it enters the wastewater system. Oil, being lighter, floats to the top, while heavier solids sink to the bottom. The cleaner water exits through a designated outlet, reducing pollutants and ensuring only treated water flows downstream.

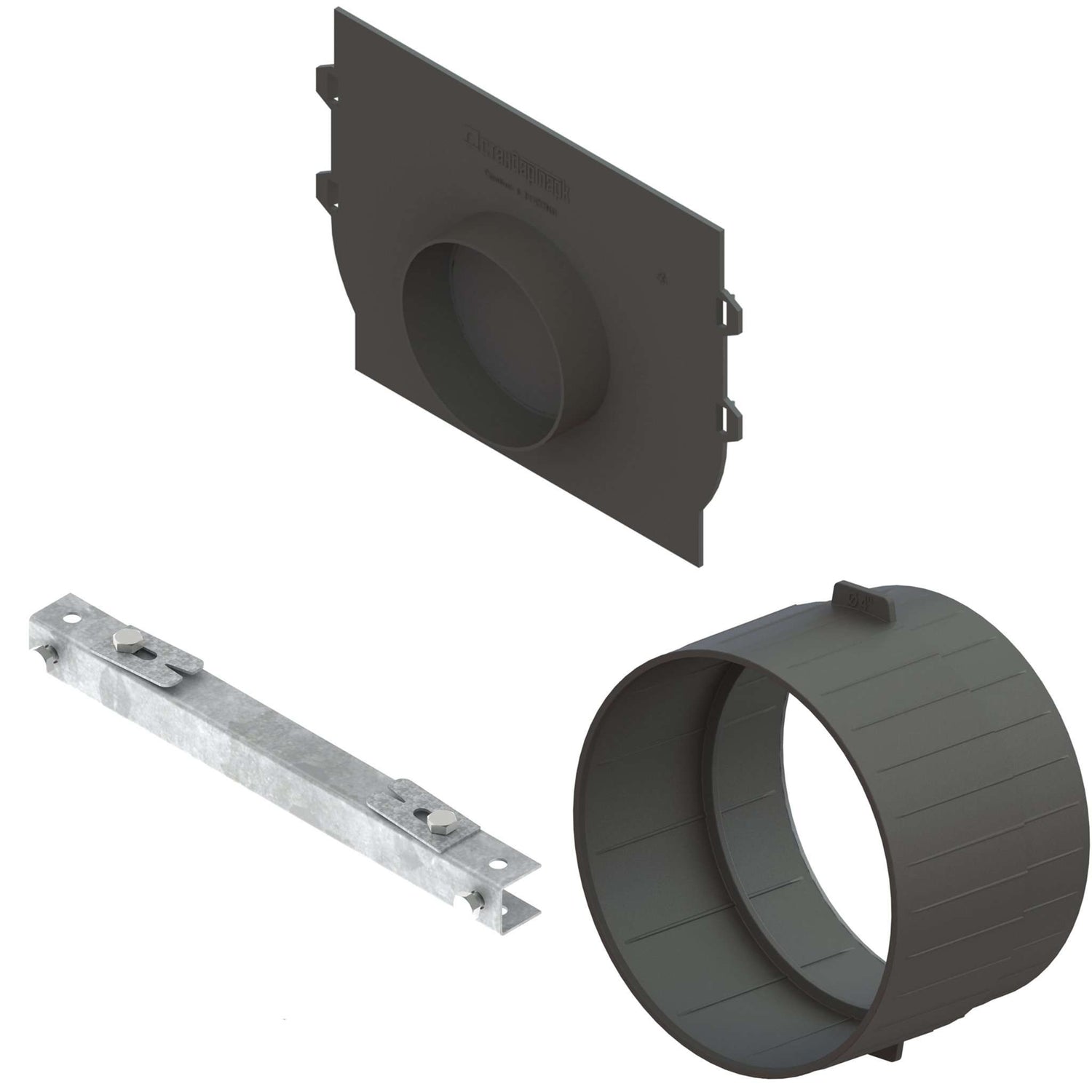

But efficiency doesn’t stop at gravity. Vodaland’s coalescing filters give our fiberglass oil/water separator systems a serious performance edge. These patented filters help oil droplets merge (or coalesce), making it easier for them to rise and separate from the water. This boosts the separation process and assures higher purity in the output stream. Once the oil is isolated, the coalescing media can be removed and serviced with minimal effort.

Why Fiberglass Wins

Material choice is a critical factor in selecting a long-lasting, reliable oil/water separator. Traditional materials like steel may offer strength but often come with weight and corrosion concerns. Vodaland’s fiberglass oil/water separator models offer a smarter alternative.

Fiberglass is corrosion-resistant, exceptionally durable, and lighter than metal, making installation faster and easier. With fewer joints or connection points, Vodaland’s single-unit fiberglass construction eliminates common leak risks. And with a smaller carbon footprint than conventional materials, fiberglass aligns well with environmentally conscious design practices.

Beyond Oil: Handling Grease and Solids

While oil separation is crucial, other industries need solutions for different types of waste. Kitchens and food service facilities benefit from Vodaland’s commercial-grade grease traps, built to withstand temperatures up to 270°F. These traps feature sediment baskets for quick debris removal, which keeps drainage systems clean and compliant.

Breweries, restaurants, and other businesses that deal with particulate-heavy waste rely on solid waste interceptors to manage the load. Vodaland’s interceptors are constructed from noncorrosive stainless steel and use gravity and a customizable three-way screen system to filter out solids effectively, even in high-acid or chemical-laden environments.

Tailored Solutions, Trusted Results

One-size-fits-all rarely works when it comes to wastewater management. That’s why Vodaland offers oil/water separators in multiple sizes and flow rates—from 70 to 215 gallons—accommodating everything from compact auto bays to large industrial washdowns. With flow rates up to 50 gallons per minute, these units support both small-scale applications and larger enterprise needs.

And when businesses need help navigating wastewater regulations or meeting specific discharge requirements, Vodaland provides products as well as guidance. By helping customers understand and apply the right systems for their setup, we enable long-term compliance and cleaner, more efficient operations.

Compliance and Cost Savings Go Hand in Hand

Falling short on environmental compliance can lead to more than just fines—it can damage reputations and stall operations. By investing in high-performance separation equipment now, businesses protect themselves against unexpected penalties while also reducing maintenance costs and system downtime over time.

More importantly, these systems help contribute to healthier communities. By ensuring that only treated water enters the environment, Vodaland’s solutions help reduce pollution, support sustainability goals, and protect municipal infrastructure.

Explore Your Options

Whether you’re specifying a project, renovating a facility, or planning a new installation, choosing the right waste separation technology is crucial. Vodaland’s full lineup of oil/water separators, grease traps, and solids interceptors provides architects, engineers, and contractors with the tools to design cleaner, safer, and more compliant spaces.

Explore Vodaland’s oil/water separator collection here and discover how these solutions can transform your wastewater management strategy. Cleaner operations don’t start with good intentions—they start with the right tools. And with Vodaland, those tools are built to last, perform, and protect.